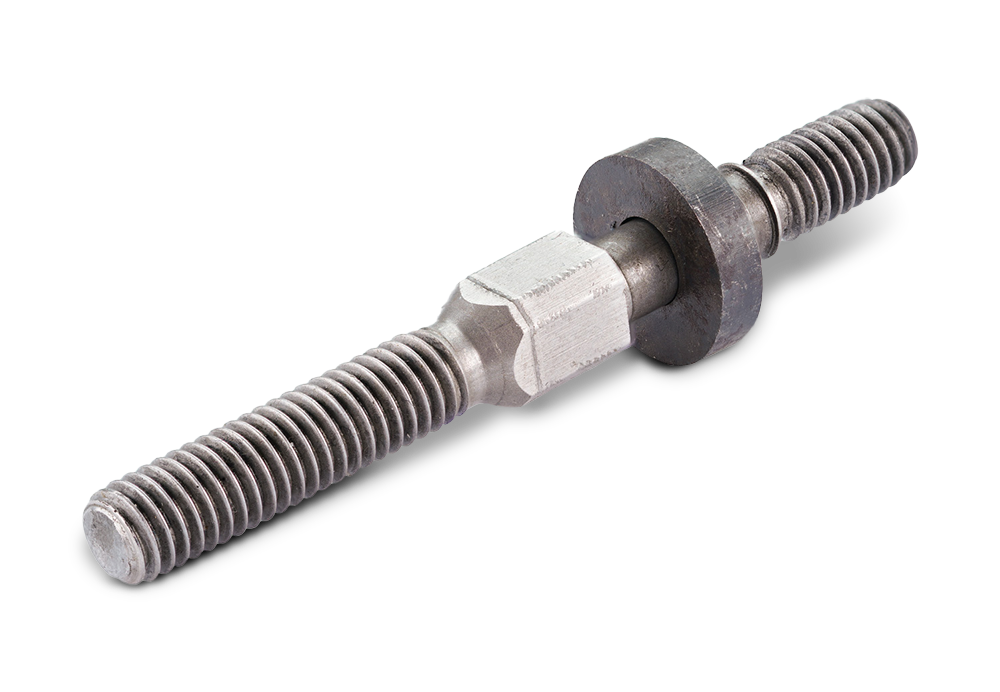

Cold Forming

Like precision mechanics with boxing gloves

Cold forming means that sections of wire are formed under pressure in two- or multi-stage tools without the addition of heat. The advantage of this process is the high production speed and, above all, the optimal utilization of material. While process-related material losses of up to 50% are not uncommon in turning and punching, the loss in cold forming is usually only 10 – 15%.

The progressive development of modern cold forming technologies leads to systems that are so precise that simple to medium-heavy turned parts can be produced much more cost-effectively by cold forming.

KOHLHAGE helps to replace such turned parts by cold formed parts and thus creates important financial leeway on the customer’s side.