Differential pressure tubes for particulate filters

KOHLHAGE helps make cars ecologically cleaner

While diesel engines have been required to have a particulate filter since September 2009, it took almost 10 years longer for petrol engines to become mandatory with the introduction of EURO 6 engines in September 2018.

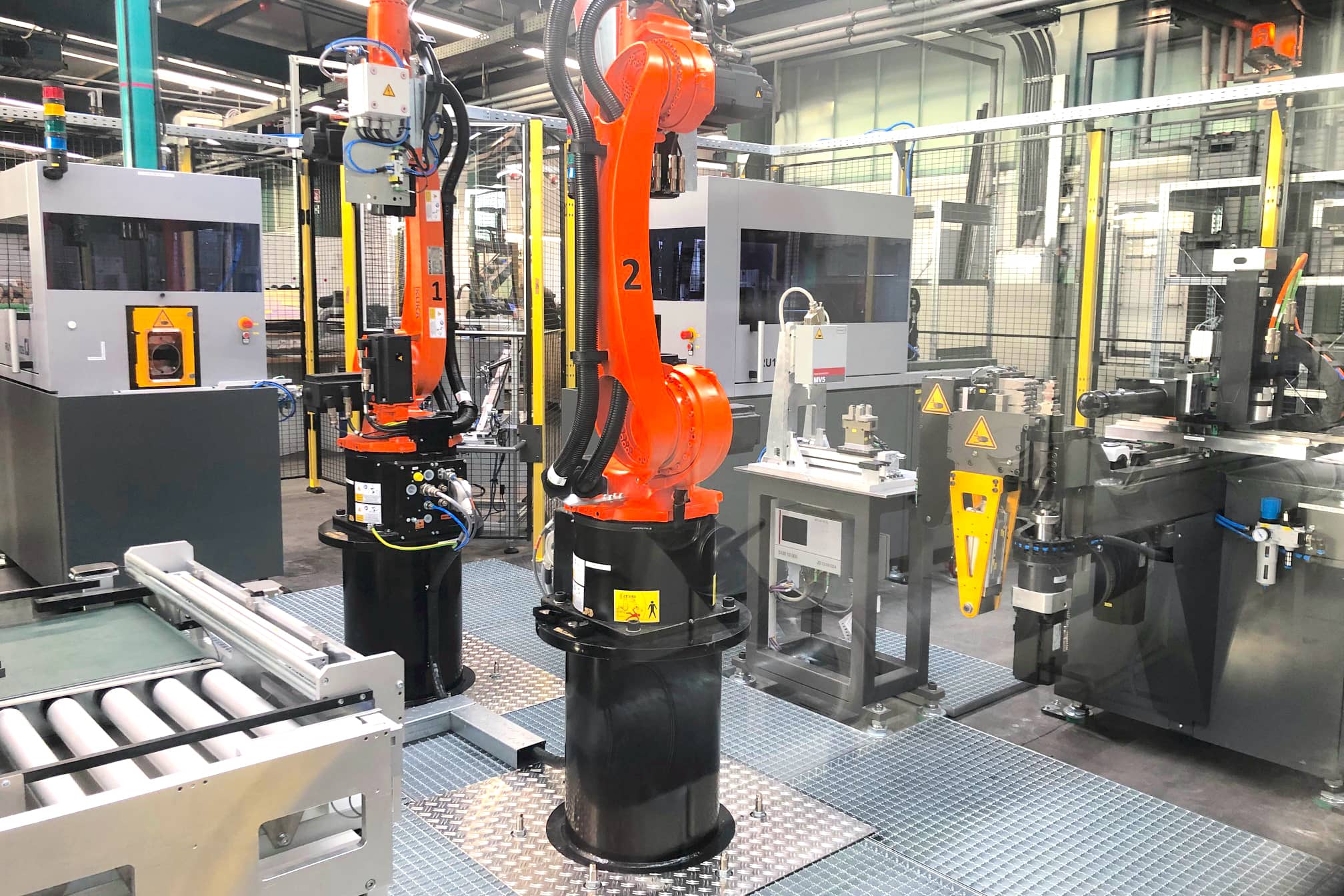

Particle filters ensure that residues from burnt fuel remain in the filter instead of simply being released into the outside air, as was previously the case. The amount of particulate matter is variable. At different engine loads, sometimes more, sometimes less residue is produced. Especially at high speeds, the amount of particles produced is enormous. An engine electronic system uses a sensor to control the pressure at which the exhaust air can flow into the particle filter. The pressure is measured at two points: In front of the filter and behind it. The pipe behind the filter that leads to the pressure sensor is called the “differential pressure pipe”. Which brings us to KOHLHAGE Automotive. Because these differential pressure lines are manufactured in Neuenrade. Recently, even on another production cell from WAFIOS.

“In the past, our production lines were often individual pieces from special machine construction,” says Christoph Brink, head of technical planning at KOHLHAGE Automotive and also responsible for the “pressure lines” production area. “We have largely moved away from this approach. Today we primarily work with manufacturers who offer modular machine concepts. This helps us with internal production control and is safer when it comes to investment planning.”

KOHLHAGE has been using WAFIOS equipment since 2005. This German supplier builds machines for spring production as well as for wire and tube bending and is an established partner at KOHLHAGE. For example, WAFIOS systems produce oil lines for a large German car manufacturer – 1.2 million units per year. The new plant directs the focus more towards flexibility rather than large quantities.

“The production of a differential pressure line involves 5 individual steps for which we previously needed 2-3 different machines. The “new one” standardises the previous individual steps and is the basis for optimising the internal machining processes,” says Brink. “But we actually bought this WAFIOS for a completely different reason: We are now as flexible in the production of differential pressure lines as we always wanted to be. Every motor vehicle needs a differential pressure line – but always a different one. The connections at the ends are standardised, fortunately. But lengths and geometries differ. For us as a manufacturer, set-up times have therefore always been a challenge. Thanks to optimised tool combinations, we can produce up to 20 different articles without time-consuming mechanical set-up processes. Buffer times are eliminated and throughput times are shorter.

This also brings us new customers. Because if a German manufacturer of sports cars only needs 2,000 lines per year, we can produce those too, in a short time and at reasonable cost.” Brink is pleased.